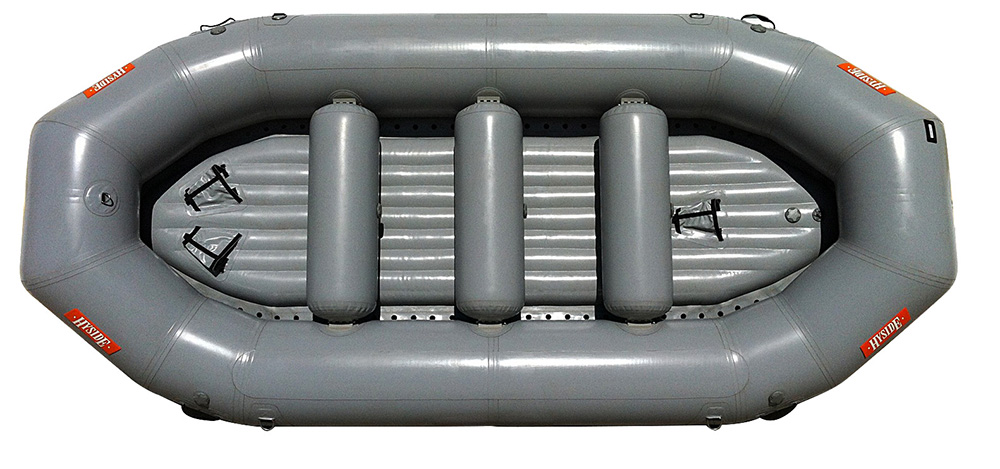

Standard Floor Vs. Self-Bailing Floor

The main difference between a standard and self bailing floor is that standard (non self-bailing) floors are sealed to the outer tubes, whereas the self-bailing floor is inflated and is either laced in or glued with holes allowing the water to exit. The floor of a self bailing raft is a wide flat inflated chamber. When inflated, the floor is about 4 or 5 inches thick, so the top surface of the floor is above the surface of the water. When water splashes into the raft, it flows across the floor, down over the edge of the floor, and out through the lacing.

Standard (non bailing) Floor

A ‘standard’ (non self-bailing, or ‘bucket’ boat) floor is sealed to the outer tubes, so that any water that enters, stays.

- Costs less than Self-Bailing floors

- If running Class I or II whitewater the inside of the boat/floor boat should stay dryer

- Requires a bucket to bail water

- When water enters, the boat becomes heavier and less maneuverable

- Chances of getting stuck on a rock is more because they are heavier with water in the boat

Self-Bailing Floor

A self-bailing floor is exactly what it says: self-bailing – the floor has holes allowing the water to exit. How and why? The floor of a self-bailing raft is a wide, flat inflated chamber. When inflated, the floor is about 4 or 5 inches thick, so the top surface of the floor is above the surface of the water. When water splashes into the raft, it flows across the floor, down over the edge of the floor, and out through the holes.

- Does not require buckets or pumps to remove water

- Much more maneuverable since any water splashing in quickly exits (in a few seconds)

- Less likely of getting stuck on a rock because the boat remains lighter

- Makes a nice mattress when flipped over

- More expensive than ‘Standard’ non-bailing floors

Quality Concerns: Avoid Cheap Inflatable Rafts

It is important to mention how important it is to avoid the cheap inflatable rafts that are commonly found in department stores these days. While these cheap inflatable rafts work fine for the local beach or small pond, if you plan on doing a long river float in these boats – especially through remote terrain or where rapids will be encountered – avoid these rafts like the plague. The lack of durability of these cheap rafts are legendary. Using these cheap inflatable rafts is a wonderful way to end up having a long walk back to the car due to the raft falling apart. The reason these inflatable rafts lack durability is that their fabric is of the cheapest variety found and quickly breaks down under UV rays, mildew, chemicals and just plain old use. Even worse, the seams of the raft (the seams are what connect the various compartments) are poorly made. As such, the seams quickly begin to either come unglued or develop holes in their own right. And once a hole or rip develops in a seam, the raft becomes useless, as repairing holes in seams is extremely difficult and rarely lasts.

Inflatable Raft Benefits for Fly Fishing

Before diving into more detail about inflatable rafts, here’s a quick run-down on the benefits of using inflatable rafts for fly fishing:

Portability

An inflatable kayak deflates and rolls up into its own carrying case. The inflatable kayak in its carrying case will weigh from 20-45 lbs (depending on the type of kayak), and can easily be lugged around and fit in any trunk. The lighter kayaks can even be backpacked in to remote locations. Inflatable kayaks are probably, second only to float tubes, the most portable fly fishing boat a person can buy.

Simple Set Up

Inflatable kayaks are incredibly simple to set up. Just take them out of the bag, lay them out flat, and inflate them to the proper pressure. Inflation can be done either with an electric pump or by using a standard bellows pump. Either method works just as well as the other to inflate the kayaks, although the electric pump does save a couple of minutes. All in all, most inflatable kayaks can be fully inflated and ready to go in about 10 minutes using a foot pump, 5-7 minutes using an electric pump.

Durability

Inflatable kayaks designed for heavy-duty river running (Class IV+) are extremely durable. An inflatable kayak rated for Class IV whitewater will withstand even the meanest encounters with rocks, logs and other obstructions year after year. Inflatable kayaks rated for Class III and under whitewater are almost as durable, because the softer fabric literally bounces the kayak off obstructions. And, should you happen to develop a puncture or tear in the kayak, it is easily fixed. Use either the supplied repair kit – which sets up quickly and allows the kayak to be back on the water in less than 30 minutes ? or a piece of duct tape for short term and emergency repairs.

Ease of Use

Inflatable kayaks are extremely simple to use, even for beginning paddlers. Paddling and maneuvering of inflatable kayaks is so simple, in fact, that beginner paddlers will quickly figure out all the basics. This is much different than a traditional hard shell kayak, which requires some skill in paddling.

Safety and Stability

Inflatable kayaks are very safe boats. Unlike canoes and traditional hard-shell kayaks, inflatable kayaks are very difficult to tip over. While you can do it, you really have to work at it. The flat bottom makes them super stable.

Capacity

For inflatable boats, inflatable kayaks have an excellent capacity. Whether you want to use it for day trips or multi-day floats, these kayaks can take all the gear you can throw in them.

Inflatable Kayaks

There are many uses for inflatable kayaks for anglers, whitewater and floating enthusiasts.

Fishing

Inflatable Kayaks are generally in the order of 10-12 feet long. This allows an angler to sit comfortably in the seat and to fly cast with accuracy. Some of these kayaks also now come with special seats that increase the height at which the angler sits, making casting even easier. Two anglers, provided they are careful with how they cast, can also fly fish from the boats at the same time.

River Running

Quality inflatable kayaks are rated to handle either Class III or Class IV whitewater, depending on how the kayak was constructed. An inflatable kayak constructed from various fabrics will be fully capable of handling Class IV whitewater while a more traditional vinyl and PVC kayak (which are less expensive) will be able to run Class III whitewater.

Multi-Day River Voyages

Inflatable kayaks have a surprisingly large capacity, exceeding that of hard shell kayaks. Capacity generally ranges from 400-600 lbs., allowing all sorts of camping gear to be taken on longer river journeys. A solo paddler in a quality inflatable kayak can easily take 300 lbs of gear, allowing for river trips of 1-2 weeks.

Lake Paddling

Inflatable kayaks are incredibly easy to paddle on lakes. The lightweight, V hull and low profile all make paddling on lakes, even in windy conditions, simple. And the paddling method to propel an inflatable kayak is extremely simple – even beginners can pick up the motions in just ten minutes or so. Many good kayaks also have the option of adding a directional skeg to them. This skeg allows the kayak to track almost perfectly straight, even when paddled by a single person. In comparison to traditional canoes, inflatable kayaks are much simpler to paddle for a single person.

Features and Benefits of Inflatable Kayaks

Portability

Inflatable kayaks are probably, second only to float tubes, the most portable fly fishing boat a person can buy. Inflatable kayaks deflate and roll up into their own carrying case. This carrying case, which will weigh anywhere from 20-45 lbs (depending on the type of kayak you have), can easily be lugged around and fit in the back of any trunk. The lighter kayaks can even be backpacked in to remote locations.

Simple Set Up

Inflatable kayaks are incredibly simple to set up. Just take them out of the bag, lay them out flat, and inflate them to the proper pressure. Inflation can be done either with an electric pump or by using a standard bellows pump. Either method works just as well as the other to inflate the kayaks, although the electric pump does save a couple of minutes. All in all, most inflatable kayaks can be fully inflated and ready to go in about 10 minutes using a foot pump, 5-7 minutes using an electric pump.

Durability

Inflatable kayaks, as they are designed for heavy duty river running, are extremely durable. An inflatable kayak rated for Class IV whitewater will withstand even the meanest encounters with rocks, logs and other obstructions. Inflatable kayaks rated for Class III whitewater are almost nearly as durable, as the softer fabric literally bounces the kayak off of obstructions. And, should you happen to develop a puncture or tear in the kayak, it is easily fixed. Use either the supplied repair kit – which sets up quickly and allows the kayak to be back on the water in less than 30 minutes. A piece of duct tape even works for short term and emergency repairs.

Ease of Use

Inflatable kayaks are extremely simple to use, even for beginner paddlers. Paddling and maneuver of inflatable kayaks is so simple, in fact, that beginner paddlers will quickly figure out all the basics. This is much different than a traditional hard shell kayak, which requires some skill in paddling.

Safety and Stability

Inflatable kayaks are very safe boats. Unlike canoes and traditional hard shell kayaks, inflatable kayaks are very difficult to tip over. While you can do it, you really have to work at it. The reason for this is because inflatable kayaks have a flat bottom, making them very stable.

Capacity

For inflatable boats, inflatable kayaks have an excellent capacity. Whether you want to use it for day trips or multi-day floats, these kayaks can take all the gear you can throw at them.

Hypalon vs. PVC Boats

Hypalon (Synthetic Rubber Coatings)

Hypalon is a synthetic rubber material patented by DuPont and is mainly used an exterior coating for inflatable boats. Hypalon can defy extreme temperature, corrosion, UV degradation, gasoline, chemicals and environmental contingencies and is considered the most reliable and durable inflatable boat fabric available. Hyside’s 80/20 Hypalon coating typically will last for more than a decade even in the roughest environments.

PVC (Plastic Coatings)

PVC is a vinyl polymer chemically known as polyvinyl chloride. It has several applications in the leisure and construction industries: making inflatable pool toys, mattresses and beach balls. Because it is a type of plastic, it can be thermo bonded or glued. This allows the manufacturer to mass produce the boats on a large scale with machines and unskilled labor. But repairs can be difficult on PVC boats because thermo welding is not feasible outside of the factory and it is very hard to repair even a pinhole leak in a seam.

|

HYPALON |

PVC |

| Highly resistant to environmental caustics (gas, chemicals, etc.) |

YES |

|

| Recommended for use in severe climates |

YES |

|

| Recommended for leaving boats inflated or for frequent use |

YES |

|

| Best properties for resisting abrasion |

YES |

|

| Fabric of choice for U.S. Military and Coast Guard |

YES |

|

| Easiest to repair leaks, etc. |

YES |

|

| Seam construction |

Overlapped or butted, then glued* |

Glued or fused together using welding** |

| Manufacturing process |

Handcrafted |

Mass produced |

| Weight (13 foot self bailing boat) |

75 to 115 lbs. |

115 to 130 lbs. |

| Colors available |

5-7 |

15+ |

| Expected life expectancy under normal river rafting use |

10-15 years |

2-3 years |

| Average cost (13 foot self bailing boat) MSRP |

$4400 |

$2000 |

*Hypalon boats are either overlapped or butted, and then glued. Butted seams produce an aesthetic, flat, airtight seam, without the ridge or air gaps left by some overlapped seams. In stress tests, Hypalon and neoprene glued seams are so strong and reliable that the fabric will fail before the seams.

**The seams of PVC-coated inflatables can be fused together using several different welding techniques. Despite many technological advancements, the heat used to weld the seams is not always distributed evenly across the seams—which creates pockets where air may escape—and welded seams tend to become brittle over time.

Fabrics coated with PVC are also more difficult to repair than those coated with Hypalon.